Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Blog Article

How an Optical Fibre Diameter Analyser Boosts Quality Control in Fibre Production

The combination of an Optical Fibre Diameter Analyser right into Fibre manufacturing procedures represents a considerable advancement in high quality control methodologies. By supplying real-time, specific measurements of Fibre sizes, this modern technology deals with the vital requirement for consistency in manufacturing standards. With its capacity to swiftly identify discrepancies and timely rehabilitative measures, the analyser not just improves product integrity but also adds to total functional effectiveness. As sectors increasingly prioritize top quality and compliance, understanding the full impact of such innovations comes to be crucial. What effects could this have for the future of Fibre production?

Significance of Fibre Diameter Measurement

Exact dimension of Fibre Diameter is essential in the area of optical Fibre technology, as it straight affects the efficiency and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying ability, depletion, and general transmission effectiveness. Accuracy in determining Fibre Diameter guarantees that the optical homes are maintained within defined resistances, which is essential for ideal signal stability.

Variants in Fibre Diameter can result in raised losses because of scattering and modal diffusion, affecting the quality of information transmission. In high-speed communication systems, such inconsistencies can cause considerable deterioration of signal high quality, leading to information mistakes and lowered performance. Furthermore, regular Fibre Diameter is crucial for compatibility with connectors and splicing innovations, which are integral parts of Fibre optic networks.

Quality control procedures in Fibre production greatly depend on exact Diameter dimensions to make sure conformity with sector standards. By carrying out robust dimension techniques, manufacturers can improve item dependability, lessen waste, and enhance total system efficiency. Thus, the importance of Fibre Diameter dimension can not be overemphasized, as it functions as a keystone in the development of optical Fibre modern technology and its applications in modern-day communication networks.

How the Analyser Functions

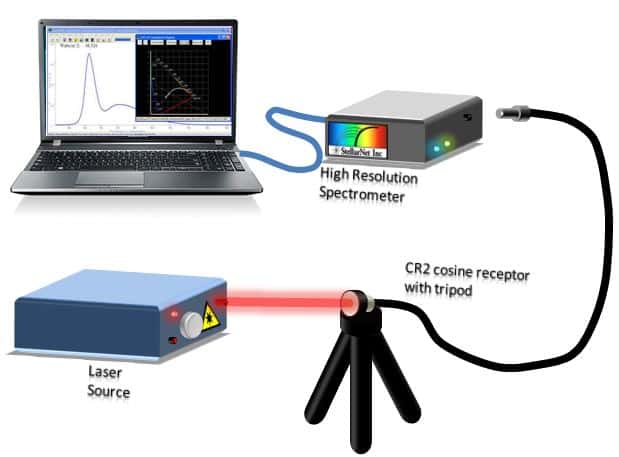

The reliable dimension of Fibre Diameter relies upon innovative logical methods that guarantee precision and integrity in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser employs a mix of laser innovation and advanced picture handling algorithms to properly assess the Diameter of fibres as they are created

Initially, a laser beam of light is routed at the relocating Fibre, creating a cross-sectional darkness. The analyser records this darkness making use of high-resolution electronic cameras placed purposefully along the assembly line. The captured photos are after that refined in real-time to identify the Fibre's Diameter with exceptional precision.

The system uses innovative formulas that represent numerous variables, consisting of variants in light intensity and ecological conditions, to boost dimension reliability. It can discover minute modifications in Diameter, such as fluctuations that might happen during the production procedure.

In addition, the analyser is qualified of dealing with multiple fibres all at once, enhancing throughput without compromising accuracy. By supplying immediate comments on the Diameter, the Optical Fibre Diameter Analyser plays a crucial function in keeping stringent quality control standards, making sure that the last item satisfies sector specs and client demands.

Advantages of Real-Time Monitoring

While traditional techniques of monitoring Fibre Diameter usually include taxing post-production checks, real-time tracking significantly boosts the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This positive approach allows suppliers to determine deviations in Fibre Diameter as they happen, as opposed to waiting until manufacturing is full to evaluate high quality

By continually measuring the Diameter throughout manufacturing, producers can make certain that the fibers satisfy stringent requirements, leading to decreased variability and enhanced consistency. Real-time monitoring also allows prompt corrective activities to be taken, lessening waste and avoiding defective fibers from going into the supply chain.

In addition, this innovation helps with improved information collection and analysis, offering insights into manufacturing fads and prospective areas for enhancement. Such data-driven decision-making empowers producers to optimize procedures and maintain high standards of quality assurance.

Furthermore, real-time monitoring fosters a culture of continual enhancement within the manufacturing setting. Employees are extra engaged when they can see the impact of their operate in real-time, causing heightened accountability and a commitment to quality. On the whole, the implementation of real-time surveillance systems in optical Fibre manufacturing converts to superior item high quality and raised consumer fulfillment.

Influence On Manufacturing Effectiveness

Implementing optical Fibre Diameter analysers substantially boosts production performance by streamlining the production process. These tools promote constant surveillance of Fibre Diameter, allowing producers to find inconsistencies in real-time. By recognizing inconsistencies without delay, assembly line can be readjusted promptly, lessening downtime and reducing the possibility of generating defective products.

Additionally, the combination of these analysers right into the manufacturing operations enables far better source allotment. With precise Diameter dimensions, drivers can optimize material use, making sure that sources are not lost on problematic fibers. This accuracy also contributes to less scrap and revamp, ultimately decreasing production costs.

The automation offered by optical Fibre Diameter analysers lowers reliance on hand-operated inspections, which are go often taxing and prone to human mistake. Because of this, workers can focus on even more calculated jobs, enhancing overall productivity.

Additionally, the data generated from these analysers can educate procedure enhancements and help with better decision-making. By evaluating fads in Fibre Diameter variants, makers can implement positive steps to boost production techniques and keep constant high quality. In summary, optical Fibre Diameter analysers play an important role in improving manufacturing efficiency, leading to webpage higher quality result and enhanced success.

Case Researches and Success Stories

Throughout different markets, study highlight the transformative impact of optical Fibre Diameter analysers on production procedures. One noticeable instance is a leading telecommunications company that encountered challenges with inconsistent Fibre diameters, resulting in raised denial rates. By incorporating an optical Fibre Diameter analyser, the company attained real-time tracking of Fibre dimensions, leading to a 30% reduction in problems and significant price savings.

In addition, a study organization concentrating on advanced products used optical Fibre Diameter analysers to fine-tune their experimental procedures. The analyser's ability to supply thorough insights right into Fibre consistency enabled the advancement of ingenious products with improved efficiency attributes.

These success tales underscore the crucial duty of optical Fibre Diameter analysers in enhancing quality assurance, enhancing manufacturing performance, pop over to this web-site and driving development throughout diverse markets.

Verdict

In conclusion, the Optical Fibre Diameter Analyser plays a pivotal role in boosting high quality control within Fibre production. As demonstrated via numerous instance research studies, the analyser verifies essential for achieving remarkable product top quality in Fibre production.

The execution of optical Fibre Diameter analysers permitted for strict top quality control, guaranteeing that the produced fibres met exacting sector standards.In final thought, the Optical Fibre Diameter Analyser plays an essential function in boosting quality control within Fibre manufacturing.

Report this page